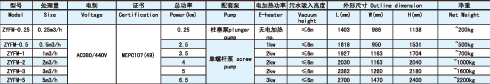

ZYFM SERIES OILY WATER SEPARATORS (15PPM BILGE SEPARATOR)

In the past four years, over thousands of our ZYFM are equiped on ships and are well received by the public home and abroad. It can be used to treat bilge oily water, and also at mines, generating station and oil depots, etc. to deal with the oily water especially that contain high emulsive oil concentration. Its’ function has reached the discharge standard stipulated by the International Maritime Organization (IMO) and also accords with the oily water discharge standard stipulated for the vessels, mines and enterprises by China. The outflow quality of the device has reached the Resolution IMO-Mepc107 (49)

The device has following characteristics:

It is constructed by The primary oil water separator, secondary emulsive oil separator, screw pump, electric control box, oily consistency detector, strainer, fine filter and 3-way valve (or solenoid valve), etc.. All of these are installed on a common seat. And if needed the primary oil water separator and electric control box may also be installed separately with secondary emulsive oil separator and oily consistency detector according to different engine room if necessary

The accessory pump does not directly draw from the oily water. Therefore, the emulsion of the oily water is avoided . And the device can gain high separating efficiency.

It use the combination of gravitational separation in vacuum and refined emulsified oil separation method. The oil drops conglomerate and float upward rapidly to the oil collecting room at the top of device when they pass through the tunnel of coalescing element in special degree and special speed. The coalescing element can backflushed it-self automatically, and there will be nearly no blockage happened. In long term usage, no replacement will be needed for coalescing element.

It has good automatic oil discharge control and safety precaution of accessory pump. And can automatically control the primary discharge process or change to the secondary discharge process by the character of the oily-water. Also can put the unqualified water back to bilge when the oil concentration in processed water is beyond the limit. The devicd is easy to operate and highly reliable, and its function accords with requirements for the 24h unattended engine rooms

It is proved that :

The effluence of the device are less than 10PPM when it treat the normal oily water (not emulsified) by using only the primary oil water separator.

The effluence of the device are less than 5PPM when it treat the emulsified oily water by using the primary and secondary separator.

ZYF SERIES OILY WATER SEPARATORS

The device has following characteristics:

The accessory pump does not directly draw from the oily water. Therefore, the emulsion of the oily water is avoided . And the device can gain high separating efficiency.

It use the gravitational separation in vacuum. The coalescing element can backflushed it-self automatically, and there will be nearly no blockage happened. In long term usage, no replacement will be needed for coalescing element.

It has good automatic oil discharge control and safety precaution of accessory pump. The devicd is easy to operate and highly reliable, and its function accords with requirements of unattended.

YNB-Ⅳ BILGE ALARM OIL CONTENT MONITOR (15PPM BILGE ALARM)

The device satisfied the IMO MEPC107 (49) requirement of International Marine Organization Marine Environment protection Committee. and got the Type Approval Certificate from CCS.

YNB-Ⅳ mensurate the oil content in sample water by the different scattered light of the elaioplast and display it by digital. When the oil content is over the setting alarm point (15PPM), the alarm is on; at the same time the excess control signal will output, which will control the outfit of bilge separation facility, alter its working mode, prevent oil stain which is over the setting point discharged directly.

MAIN TECHNICAL PARAMETERS

Masuring range: 0-100 PPM

Sypply voltage: 110V/220VAC

Power: 30 VA

Alarm range: 1-50 PPM (set according to demand)

Default alarm point: 15 PPM

Alarm delay: alarm 1: <2S , alarm 2: 2-8S

Capacity of the signal output terminal: 3A/240V AC

Alarm display: LED RED

Sample water pressure: 0.1-0.5 bar

Sample water current speed: about 1 L/min

Memory capacity: 64k (18 months’ data at least)

Type of printer: dot matrix printer, use ordinary roll of paper with width of 57.5mm

Temp Range: 0℃-50℃

Overall dimension: 460×300×180 mm

Weight: 15Kg

The IMO-MEPC.107(49) resolution regulates the design and performance of the oily water separators and the 15 ppm Bilge Alarms for machinery space bilges of ships. Each ship must have a certified 15 ppm bilge alarm for measuring the oil content in the discharge water. The 15ppm Bilge Alarm shall give an alarm and initiate automatic stop of overboard discharge of oily mixtures, according to the latest requirements.

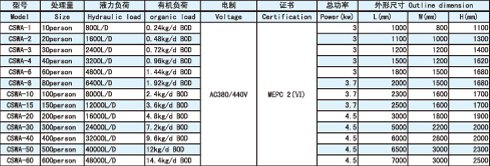

CSWA SERIES SEWAGE TREATMENT PLANTS

Effluent standard of CSWA Series Sewage Treatment Plants:

Biochemical Oxygen Demand (BOD5) not exceed 50 mg/l

Total Suspended Solids (TSS) not exceed 50 mg/l

Thermotolerant Coliform not exceed 250 thermotolerant coliforms/100 mlas

PH between 6 and 8.5.

CSWB SERIES SEWAGE TREATMENT PLANTS

Due to the combination of sequence batch reactor (SBR) ,UV disinfection, and membrane bioreactor filter(MBR)technique. The equipment can change the growing environment of activated sludge by time sequencing and realize the aerobic, anaerobic mode. It can reduce the BOD, COD index rapidly and efficiently, and also has good denitrification and dephosphorization effects. Then achieve a super complete biochemical treatment performance. The equipment can also adapt to the vacuum system with higher concentration of sewage. It has good Impact resistance of stream and organic dirt, compact conformation, and avert the secondary pollution. The equipment are controled by PLC program. The hole controle system are with high degree of automation , high reliability, easy to operate. fully reaching unattended operation requirement.

The effluent of CSWB Series Sewage Treatment Plants can up to the standard of amended MAPOL73/78 and resolution MEPC.159(55). It had already got the Type Approval Certificate by CCS and classification societies abroad.

Effluent standard of CSWB Series Sewage Treatment Plants:

Total Suspended Solids (TSS) not exceed 35 mg/l

Biochemical Oxygen Demand (BOD5) not exceed 25 mg/l

Chemical Oxygen Demand (COD) not exceed 125 mg/l.

Thermotolerant Coliform not exceed 100 thermotolerant coliforms/100 mlas

PH between 6 and 8.5.

About MEPC.159(55)

The Marine Environment Protection Committee(MEPC) of the International Maritime Organization (IMO) adopted resolution IMO.MEPC.159(55) on 13 October 2006. It amends the “MARPOL 73/78 International Convention for the Prevention of Pollution from Ships” ANNEX Ⅳ about the requirements of marine sewage treatment plants. All equipment installed on board on or after 1 January 2010 should meets the revised guidelines .

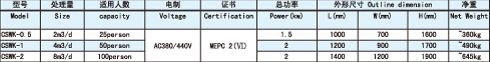

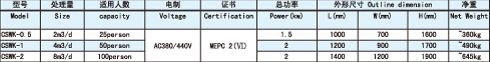

CSWK SERIES SEWAGE BREAKING STERILIZER

Effluent standard of CSWK Series Sewage Breaking & Sterilizing Cabinet:

Thermotolerant Coliform not exceed 1000 thermotolerant coliforms/100 mlas

Total Suspended Solids (TSS) not exceed 50 mg/l

Main Feature

The device is simple and dependable

Has a small overall dimensions, cheap in price

Easy operation, high degree of automation

High performance, wild range of application

The effluence can meet the IMO standard